Why use Laser 2000 as your optical supply partner?

Our deep knowledge of the industry is what adds value to working with Laser 2000. We maintain very close relationships with our manufacturers, and systematically check to make sure that they meet our exacting standards. Although many of the manufacturers we deal with are based outside of the UK, we know them personally so that when their support is needed, we and your project are not just a number for them.

Since the 1990’s, Laser 2000 has been at the forefront of optics and photonics technologies. We delight in helping our customers achieve their goals through the application of photonics. By recruiting, training and developing highly skilled staff we can advise and educate our customers about photonic.

Our optics business is split into mainly two customer groups.

- OEM custom from concept to volume production, providing optical components, assemblies or optical sub systems

- Off-the-shelf optics and optomechanics working with our long established partners

Please use the menu on the left to navigate to your required section

OEM from concept to volume production

As a team we listen to and understand our customer requirements, which involves interacting not only technically with engineering & development but also understanding the commercial and operational restrictions.

Initially we work to understand and evaluate the technical feasibility. In specifying a technical solution we can prioritise which specifications are key and modify others in accordance with needs. The advantage of being a value added reseller is that we have worked with customers in many segments from life science to space, gaining tremendous experience and expertise along the way.

Over the years of enquiries, this added value has been rewarded with many strategic partnerships with our customers and suppliers.

Building valued strategic partnerships with our customers

Engineering & Development

- Introducing emerging & disruptive yet robust technologies to bring competitive advantage and solve the most complex photonics needs

- Solution development & test to meet complex requirements, in close partnership with customers

- Leading the successful delivery of complex programmes for customers, managing risk to ensure robust outcomes

Operations

- Inventory management & local stock holding to SIOP Plan requirements to meet pull demand signals

- Continuity: Spares / failure safety stock holding & rapid response

- Assisting customers with Training, Process Transformation & Change Management

Procurement

- Risk reduction (inc. supplier resilience & running multi-sourcing for customers; extensive Brexit mitigation plans in place)

- Purchase cost reduction (inc. value engineering)

- Vendor reduction

- Transaction count reduction

- Supplier quality management

- Consumables re-stocking / re-kitting & inventory buffering

Custom Optics, assemblies and sub-assemblies

Custom Optic Specification capabilities

- Surface flatness: λ/10 – λ/50 for a diameter of 150mm

- Roughness: RMS 2Å – 3Å

- Angle precision: ± 1″

- Scratch & Dig: 10-5

- Dimension tolerances: ±0.05mm to ±0.001mm

- Parallelism: <1″

- Reflectance: R>99.999% reached!

- Substrate thickness: 0.08mm achieved

- Freeform Optics

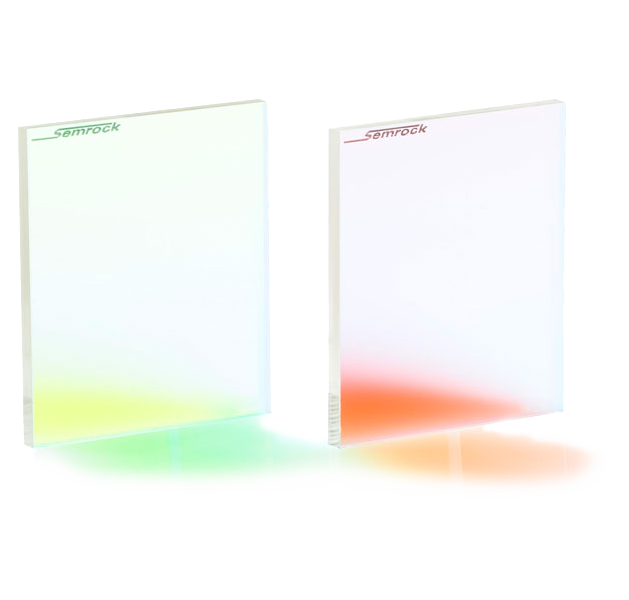

Custom Filters

Working with Idex Health & Science (Semrock), pioneering experts in optical filters for life science, analytical instrumentation, and medical diagnostics applications, we have continually set the standards for advanced performance and reliability. Our unwavering commitment to quality and customer service allows us to consistently deliver much more than just filters.

Semrock specialises in the volume production of optical filters featuring hard, thin-film sputtered coatings for proven reliability. These filters will not change or degrade in any way as a result of humidity or temperature variations, nor will they “burn out” with normal use.

Semrock products are backed by their industry-leading ten-year warranty.

Shorten time-to-market, improve your engineering productivity and final system performance by taking full advantage of our proprietary design software SearchLight™

Polarisation Optics

From small precision optics, such as our micro-retarders, less than 20 microns thick and millimetres per side used in the telecommunications industry to 200mm diameter waveplates used in astronomy, Laser 2000 and our partners have the knowledge and experience to solve your problem.

Over the years we have been asked to deliver some unique polarisation components. Our reputation for quality and innovation has made us the company that many people turn to when they need a device that is not readily available.

Other examples of these devices include a segmented polariser that contained four different quadrants, where each quadrant had its polarisation transmission axis in a different orientation. Custom Liquid Crystal components and Spatial Light Modulators.

Take a look at our standard off-the-shelf phase & polarisation control components for ideas!

Freeform Optics

A freeform optic (refractive or reflective) is a surface that are designed with little to no rotational symmetry or where the rotational symmetry is decentered off the optical axis. Due to the complexity of design and manufacture these are typically more expensive than standard symmetrical optics so should only be considered when this can reduce the number of elements in an optical system allowing for more efficient, smaller form factor and lighter optical systems.

| Attribute | Tolerancing Limit |

|---|---|

| Diameter (mm) | +0, -0.010 |

| Centre Thickness (mm) | ± 0.050 |

| Irregularity – Interferometry (HeNe fringes) | 0.1 (stiching/CGH dependent) |

| Irregularity – Profilometry (µm) | ± 1.0 |

| Surface Roughness (Å RMS) | 10 |

Off-the-shelf optics

Laser 2000 partners with many globally recognised partners and brands in providing both custom and off-the-shelf products. Our partner for lifescience filters is Idex Health and Science (Semrock) and for classical optics such as mirrors, lenses, polarisation optics, substrates and sub-assemblies we partner with Optosigma Europe (OSE) and Meadowlark Optics.

The following sections will provide a brief description of products with links to their catalogue pages or webpage location

Substrates and Windows

Please download our substrate and windows catalogue here

Uncoated optical glasses (substrates) used for mirrors or beamsplitters.

| Substrates | Windows |

|---|---|

| Low scattering substrates | AR Coated |

| Optical flats & float glass | AR coated for high power lasers |

| Optical parallels and flats with holes | IR Windows (SFS, Al2 O3 , CaF2, ZnSe, Ge, Si) |

| Wedged substrates | UV Windows |

| Custom curved mirrors | Brewster Windows |

Lenses

A lens is a transmissive optical device that focuses or disperses a light beam by means of refraction. A simple lens consists of a single piece of transparent material, while a compound lens consists of several simple lenses (elements), usually arranged along a common axis. Lenses are made from materials such as glass or plastic, and are ground and polished or moulded to a desired shape.

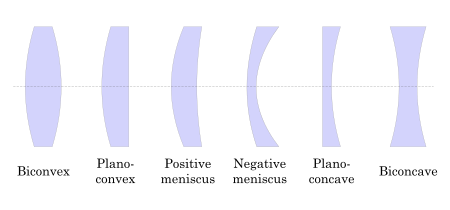

Most lenses are spherical lenses: their two surfaces are parts of the surfaces of spheres. Each surface can be convex (bulging outwards from the lens), concave (depressed into the lens), or planar (flat). The line joining the centres of the spheres making up the lens surfaces is called the axis of the lens.

Lenses are classified by the curvature of the two optical surfaces. A lens is biconvex (or double convex, or just convex) if both surfaces are convex. If both surfaces have the same radius of curvature, the lens is equiconvex. A lens with two concave surfaces is biconcave (or just concave). If one of the surfaces is flat, the lens is plano-convex or plano-concave depending on the curvature of the other surface. A lens with one convex and one concave side is convex-concave or meniscus. It is this type of lens that is most commonly used in corrective lenses.

If the lens is biconvex or plano-convex, a collimated beam of light passing through the lens converges to a spot (a focus) behind the lens. In this case, the lens is called a positive or converging lens. For a thin lens in air, the distance from the lens to the spot is the focal length of the lens, which is commonly represented by f in diagrams and equations.

Cylindrical lenses are based on a cylindrical instead of spherical geometry and therefore have a different radii in the X and Y axes. They are commonly used to correct for astigmatism in imaging or laser systems, but are also used as laser line generators in applications such as machine vision.

Achromatic lenses (or Achromats) can be both spherical and cylindrical and consist of two or more optical components cemented together or in a lens assembly, These lenses have noticeable advantages over traditional single element lenses mainly compensating for Chromatic Aberrations, which is where the focal position is different for different colours (wavelengths), but also spherical and coma aberrations.

Please click on the links below to download the catalogue section

| Spherical Lenses | Cylindrical Lenses | Achromatic Lenses | Speciality Lenses | IR lenses |

|---|---|---|---|---|

| Plano Convex Lenses – Fused silica (SLSQ-P Series) – Excimer synthetic FS (SLSQK-P Series) – BK7 (SLB-P Series) | Plano Convex Lenses – Fused silica (CLSQ-P Series) – BK7 (CLB-P Series) | Visible Achromats – Crown/Flint Glass (ATL-NADL Series) NIR Achromatic – N-LAK22, SF6 (DL-PNIR Series) | Fly-Eye Lens -B270 (FEL Series) | Plano Convex Lenses – Silicon (SLSI Series) |

| Plano Concave Lenses – Fused silica (SLSQ-N Series) – Excimer synthetic FS (SLSQK-N Series) – BK7 (SLB-N Series) | Plano Concave Lenses – Fused silica (CLSQ-N Series) – BK7 (CLB-N Series) | Achromatic Doublets – BK7, SF2 (DLB Series) | Fresnel Lens – Acrylic CLAREX (FRL Series) | Plano Convex Lenses – Sapphire (SLSH Series) |

| Biconvex Lenses – Fused silica (SLSQ-B-P Series) – Excimer synthetic FS (SLSQK-B-P Series) – BK7 (SLB-B-P Series) | Rod Lenses -BK7 (RODB) | Negative Achromatic – N-BAF10, N-SF10 (DL-NM Series) | Micro Spheres – LaSF9 (MS Series) Micro Lenses – LaSF9; SK2; BK7 – (SLM Series) | Plano Convex Lenses – Germanium (SLGE Series) |

| Bioconcave Lenses – Fused silica (SLSQ-B-N Series) – Excimer synthetic FS (SLSQK-B-N Series) – BK7 (SLB-B-N Series) | Cylindrical Achromatic – N-SF5, BK7 (CDL Series) | Low Cost Achromatic – BK7, SF2 (S-DLB Series) | Aspheric Condenser Lenses – B270 (AGL Series) | Plano Convex Lenses – Calcium Fluoride (SLCFU Series) |

| Plano Convex Lenses – ZnSe (SLZS Series) |

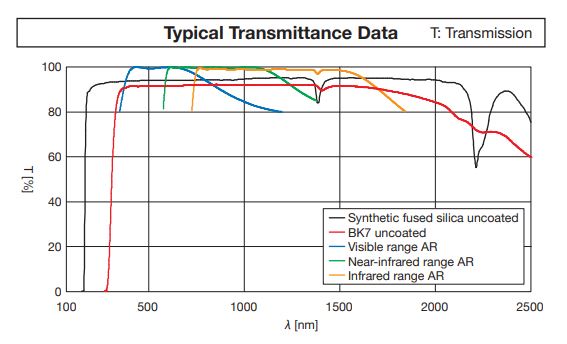

| Type of AR coating | Part No. Suffix | Wavelength Range (nm) | Transmittance (%) |

|---|---|---|---|

| Visible range | M | 400 – 700 | > Average 99 |

| Near-infrared range | IR1 | 633 – 1064 | > Average 98.5 |

| Infrared range | IR2 | 750 – 1550 | > Average 98.5 |

Multi-element Lenses & Lens Assemblies

Please download our Multi-element lens catalogue here

Multi-element lenses and lens assemblies are when lenses of various types are assembled to meet the requirements of the imaging system. This can be as simple as a Galilean beam expander which can be used to expand a collimated beam for high powered laser applications to microscope objectives which can range from a simple two element achromat to fifteen plus elements such as in plan-apochromatic objectives, which correct for many more aberrations.

- Laser Beam Expanders with dioptre correction function

- Collimating Lens

- Focussing lenses for YAG, Fibre and Excimer lasers

- Achromats – UV

- F-theta lenses

Mirrors

Please download our Mirror catalogue here

A mirror is a wave reflector. Light consists of waves, and when light waves reflect off the flat surface of a mirror, those waves retain the same degree of curvature and vergence, in an equal yet opposite direction, as the original waves. The light can also be pictured as rays (imaginary lines radiating from the light source that are always perpendicular to the waves). These rays are reflected at an equal yet opposite angle from which they strike the mirror (incident light). This property, called specular reflection, distinguishes a mirror from objects that diffuse light, breaking up the wave and scattering it in many directions (such as flat-white paint). Thus, a mirror can be any surface in which the texture or roughness of the surface is smaller (smoother) than the wavelength of the waves.

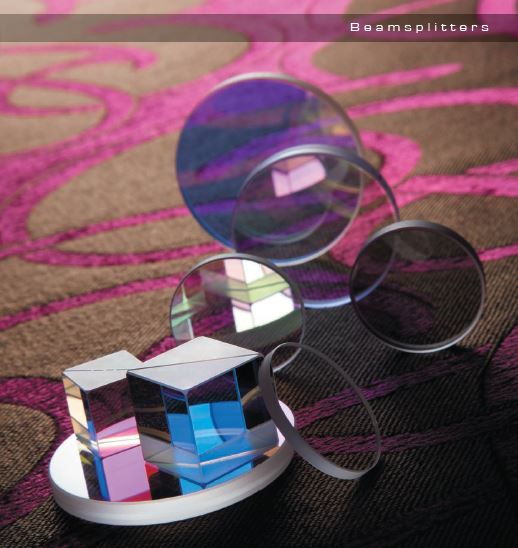

Beamsplitters

Please download our Beamsplitter catalogue here

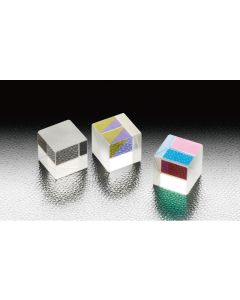

Beamsplitters are often classified according to their construction, with the most common being Cube and Plate beamsplitters. These components are used to split light into two separate beams or two combine to separate beams.

Cube beamsplitters are constructed from two right angle prisms where the hypotenuse surface is coated and the two prisms are cemented together. Easy to be applied in an optical design, but becomes expensive for large beam sizes. As the optical path length is longer than for a plate, the chromatic dispersion tends to be higher than plates, but it eliminates the problem of beam deviation.

Plate beamsplitters are good for large beam applications at a reasonable price. They have a lower chromatic dispersion and minimal back reflection, but there can be a slight offset of the transmitted beam due to refraction. For 45° AOI the clear aperture would be elliptical and there may be some vignetting.

| Type | Image | Application | Polarization constraints received when laser light is used |

| Non-polarizing (NPCH} B046 |  | For high accuracy laser experiment with accurate light ratios at any polarization levels. | The light ratios at 1:1 stay stable even when the polarization situation changes. No power loss. |

| Hybrid (HBCH} B048 |  | For multi-wavelength light splitting solutions. | Light ratio at 1:1 from any specified light incident direction will remain similar. |

| Laser Line Plate (PSMH} B055 |  | Large beam size, multi mirror optical set up with small power light source and supports high power laser light splitting. | Polarization at 45 degree (AOI) or circle polarization light with no power loss detected. |

| Chromium Plate (PSCH} B058 |  | Large beam size and observation optical system. | Polarization at 45 degree (AOI) or circle polarization light with 36% absorption of light power. |

| Chromium Cube (CSCH} B049 |  | For basic laser experiments and compact optical solutions. Great entry level price. | Polarization at 45 degree (AOI) or circle polarization light with 40% absorption of light power. |

| Dielectric Cube (CSMH} B050 |  | For general white light and non-polarizing light i.e. LED light splitting solutions. | Polarization at 45 degree (AOI) or circle polarization light with no power loss detected. |

Prisms

Please download our Prism catalogue here

Glass polished into certain geometric shapes can have a significant impact on the properties of light, such as simple dispersion to changing the ‘handedness’ of an image.

There are four main types of prisms

- Dispersion Prisms

- Reflection Prisms

- Rotation Prisms

- Displacement Prisms

A dispersing prism depends on the refractive index and geometry of the glass. Where prisms that deviate light, rotate the image, or simply displace the image from its original axis are used in many imaging systems.

Waveplates (Retarders), Polarisers and Polarising Beamsplitters

When choosing a polarisation components it is normally a balance of several key considerations: cost, wavelength range, aperture size, acceptance angle, damage threshold, transmission efficiency, and extinction ratio.

For more information please read the section Polariser Selection “Guide” in our blog Polarisation & phase manipulation with retarders (waveplates)

Waveplates (Retarders)

A waveplate (retarder) is an optical device that resolves a light wave into two orthogonal linear polarisation components and produces a phase shift between them. The resulting light wave is generally of a different polarisation form. Ideally, retarders do not polarise, nor do they induce an intensity change in the light beam, they simply change its polarisation form.

We supply Polymer and crystalline waveplates and depolarisers, that can be true zero-order, compound zero-order and achromatic.

Polarisers, polarising prisms and polarising beamsplitters

Polarisers come in three main forms: Linear; Beam-splitting and Circular.

Linear Polarisers

Ideal linear polarisers transmit 100% of the light when the incoming light is polarised and aligned with the polarisation axis or 50% if the incoming light is unpolarised.

The ratio between the transmission of the desired polarisation direction and the undesired orthogonal polarisation direction is the contrast or extinction ratio.

Beamsplitting Polarisers

Beamsplitting polarisers separate the incoming unpolarised light into two (usually) orthogonally polarised beams. Most commonly this is done via birefringent crystals such as Calcite via beam splitting cubes or polarising prisms.

Other beamsplitters such as wire grid polarisers constructed of a thin layer of aluminium microwires allow for durability, contrast and a wide field of view through to IR wavelengths.

Circular Polarisers

Mainly used for optical isolation with two main designs:

1) Dichroic circular polarisers/zero-order retarder

2) Beamsplitting polariser/zero-order retarder

Both designs take advantage of the handedness change of a circularly polarised beam upon reflection. By changing the handedness of the circularly polarised beam, back reflections are blocked by the polariser.

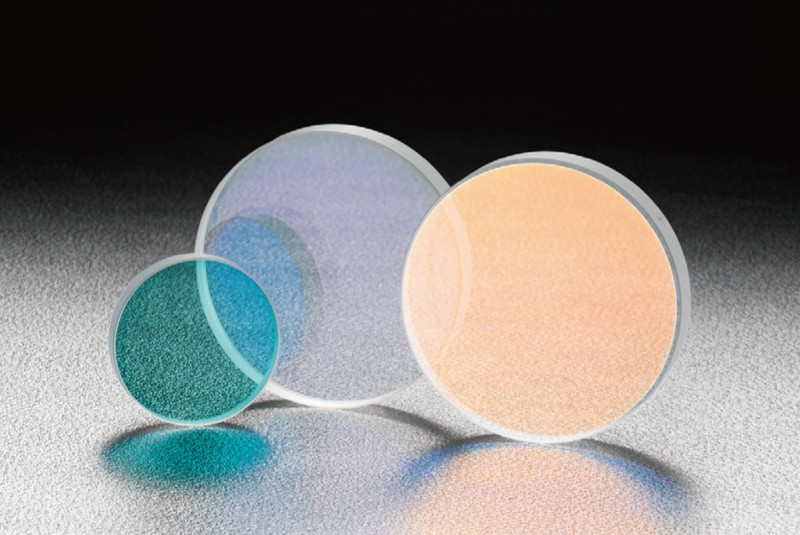

Optical Filters

Microscopy Filters

Working with Idex Health & Science (Semrock) we provide off-the-shelf optical filters for fluorescence microscopy that are hard coated, with a patented construction giving superior performance. Steeper edges, precise wavelength accuracy and optimised blocking give better contrast and faster measurements, even at UV wavelengths. These filters do not burn out and can be handled and cleaned safely. Their simple structure and hard coating makes them virtually impervious to humidity and temperature induced degradation.

Please see our Filters for Microscopy section here

Or if you’re looking for filters to use with a particular fluorophore, you can find compatible filter sets from the listings shown here.

Consider making use of Semrock’s free, online spectral plotting and analysis tool, SearchLight. This allows fluorescence microscope users and optical instrument designers to model and evaluate the spectral performance of fluorophores, filter sets, light sources, and detectors as components of an overall system.

All standard filters have a 10-year warranty. The 30-day free trial period allows you to try before you buy, and ensure that the filter set meets your needs.

ND Filters

Please download our Filter catalogue here

There are many different filters available but they can be broadly grouped by requirement as:

- Brightness Adjustment –

Fixed and variable absorptive or reflective ND Filters - Choice of wavelength –

Coloured glass, etalons, dichroic and band pass filters - Attenuate scattered light –

Diffuser and beam shaping diffusers

Optomechanics

Please download our Optomechanics Holder catalogue here and our bases catalogue here

| Example Holders | Example Bases |

|---|---|

| Kinematic mirror mounts | Optical tables |

| Vertical control mirror mounts | Vibration control |

| Gimballed mirror and beamsplitter holders | Optical breadboards |

| Beam steering assemblies | Vibration Isolators |

| Lens mounts | Optical rails |

| V-groove lens holders | Base plates & clamps |

| Caliper variable lens holders | Pedestals & posts |

| Multi-element and Objective lens holders | Post holders, spacers |

| Prism Holders | Poles |

| Spatial Filters, pinholes and slits | Z-brackets |

Here to help!

We are here to help! Speak to one of our experts who can guide you to the correct product